Using EAGLE: Board Layout

Step EAGLE PCB design: from

placing parts, to routing them, to generating gerber files to send to a

fab house. The basics of EAGLE’s board editor,

beginning with explaining how the layers in EAGLE match up to the layers

of a PCB.

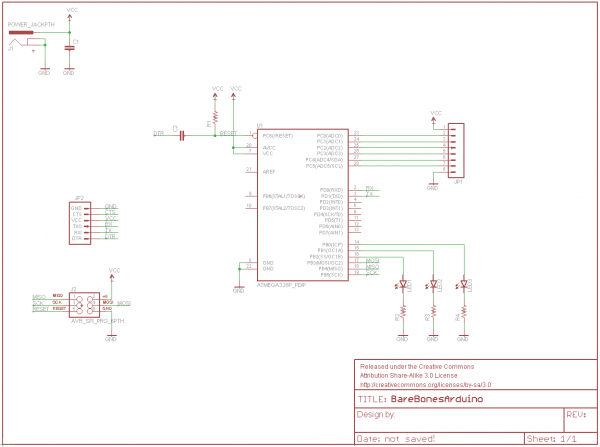

Create a Board From Schematic

Before starting this tutorial, read through and follow along with the

Using EAGLE: Schematic tutorial (not to mention the

Setting Up EAGLE tutorial before that). The schematic designed in that tutorial will be used as the foundation for the PCB designed here.

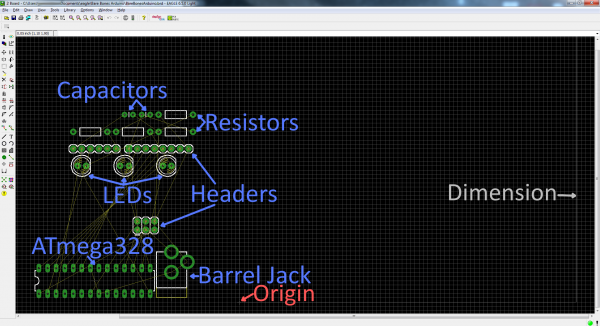

The schematic from previous tutorial,

complete with an ATmega328P, barrel jack connector, LEDs, resistors,

capacitors, and connectors.

To

switch from the schematic editor to the related board, simply click the

Generate/Switch to Board command –

(on the top toolbar, or under the

File

menu) – which should prompt a new, board editor window to open. All of

the parts you added from the schematic should be there, stacked on top

of eachother, ready to be placed and routed.

The board and schematic editors share a few similarities, but, for

the most part, they’re completely different animals. On the next page,

we’ll look at the colored layers of the board editor, and see how they

compare to the actual layers of a PCB.

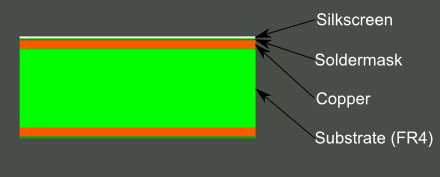

Layers Overview

PCB composition is all about layering one material over another. The thickest, middle part of the board is a insulating substrate (usually

FR4). On either side of that is a thin layer of

copper,

where our electric signals pass through. To insulate and protect the

copper layers, we cover them with a thin layer of lacquer-like

soldermask, which is what gives the PCB color (green, red, blue, etc.). Finally, to top it all off, we add a layer of ink-like

silkscreen, which can add text and logos to the PCB.

The layers of a double-sided PCB (image from the PCB Basics tutorial).

EAGLE’s Layers

The EAGLE board designer has layers just like an actual PCB, and they

overlap too. We use a palette of colors to represent the different

layers. Here are the layers you’ll be working with in the board

designer:

| Color | Layer Name | Layer Number | Layer Purpose |

|---|

| Top | 1 | Top layer of copper |

| Bottom | 16 | Bottom layer of copper |

| Pads | 17 | Through-hole pads. Any part of the green circle is exposed copper on both top and bottom sides of the board. |

| Vias | 18 | Vias.

Smaller copper-filled drill holes used to route a signal from top to

bottom side. These are usually covered over by soldermask. Also

indicates copper on both layers. |

| Unrouted | 19 | Airwires. Rubber-band-like lines that show which pads need to be connected. |

| Dimension | 20 | Outline of the board. |

| tPlace | 21 | Silkscreen printed on the top side of the board. |

| bPlace | 22 | Silkscreen printed on the bottom side of the board. |

| tOrigins | 23 | Top origins, which you click to move and manipulate an individual part. |

| bOrigins | 24 | Origins for parts on the bottom side of the board. |

| / / Hatch | tStop | 29 | Top stopmask. These define where soldermask should not be applied. |

| \ \ Hatch | bStop | 30 | Absent soldermask on the bottom side of the board. |

| Holes | 45 | Non-conducting (not a via or pad) holes. These are usually drill holes for stand-offs or for special part requirements. |

| tDocu | 51 | Top documentation layer. Just for reference. This might show the outline of a part, or other useful information. |

To turn any layer off or on, click the “Layer Settings…” button –

– and then click a layer’s number to select or de-select it. Before you

start routing, make sure the layers above (aside from tStop and bStop)

are visible.

Selecting From Overlapping Objects

Here’s one last tip before we get to laying our board out. This is an

interface trick that trips a lot of people up. Since the board view is

entirely two-dimensional, and different layers are bound to overlap,

sometimes you have to do some finagling to select an object when there

are others on top of it.

Normally, you use the mouse’s left-click to select an object (whether

it’s a trace, via, part, etc.), but when there are two parts

overlapping

exactly where you’re clicking, EAGLE doesn’t know

which one you want to pick up. In cases like that, EAGLE will pick one

of the two overlapping objects, and ask if that’s the one you want. If

it is, you have to

left-click again to confirm. If you were trying to grab one of the other overlapping objects,

right-click to cycle

to the next part. EAGLE’s status box, in the very bottom-left of the

window, provides some helpful information when you’re trying to select a

part.

For example: In the GIF above, a

VCC net overlaps another named

Reset. We left-click once directly where they overlap, and EAGLE asks us if we meant to select

VCC. We right-click to cycle, and it asks us instead if we’d like to select

Reset. Right-clicking again cycles back to

VCC, and a final

left-click selects that as the net we want to move.

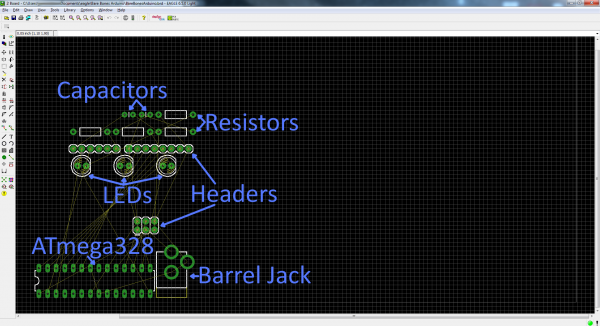

Arranging the Board

Create a Board From Schematic

If you haven’t already, click the

Generate/Switch to Board icon –

– in the schematic editor to create a new PCB design based on your schematic:

The new board file should show all of the parts from your schematic. The gold lines, called

airwires,

connect between pins and reflect the net connections you made on the

schematic. There should also be a faint, light-gray outline of a board

dimension to the right of all of the parts.

Our first job in this PCB layout will be arranging the parts, and

then minimizing the area of our PCB dimension outline. PCB costs are

usually related to the board size, so a

smaller board is a cheaper board.

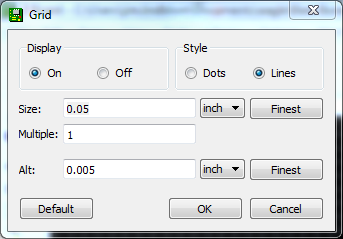

Understanding the Grid

In the schematic editor we never even looked at the grid, but in the

board editor it becomes much more important. The grid should be visible

in the board editor. You can adjust the granularity of the grid, by

clicking on the GRID icon –

. A 0.05" grid, and 0.005" alternate grid is a good size for this kind of board.

EAGLE forces your parts, traces, and other objects to “snap” to the grid defined in the

Size box. If you need finer control, hold down ALT on your keyboard to access the

alternate grid, which is defined in the

Alt box.

Moving Parts

Using the MOVE tool –

– you can start to move parts within the dimension box. While you’re moving parts, you can

rotate them by either right-clicking or changing the angle in the drop-down box near the top.

The way you arrange your parts has a huge impact on how easy or hard

the next step will be. As you’re moving, rotating, and placing parts,

there are some factors you should take into consideration:

- Don’t overlap parts: All of your components need

some space to breathe. The green via holes need a good amount of

clearance between them too. Remember those green rings are exposed

copper on both sides of the board, if copper overlaps, streams will cross and short circuits will happen.

- Minimize intersecting airwires: While you move

parts, notice how the airwires move with them. Limiting criss-crossing

airwires as much as you can will make routing much easier in the long run. While you’re relocating parts, hit the RATSNEST button –

– to get the airwires to recalculate.

– to get the airwires to recalculate.

- Part placement requirements: Some parts may require

special consideration during placement. For example, you’ll probably

want the insertion point of the barrel jack connector to be facing the

edge of the board. And make sure that decoupling capacitor is nice and close to the IC.

- Tighter placement means a smaller and cheaper board, but it also makes routing harder.

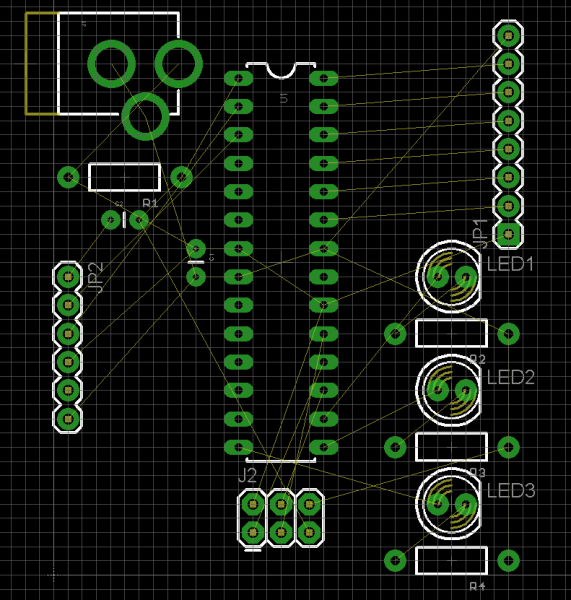

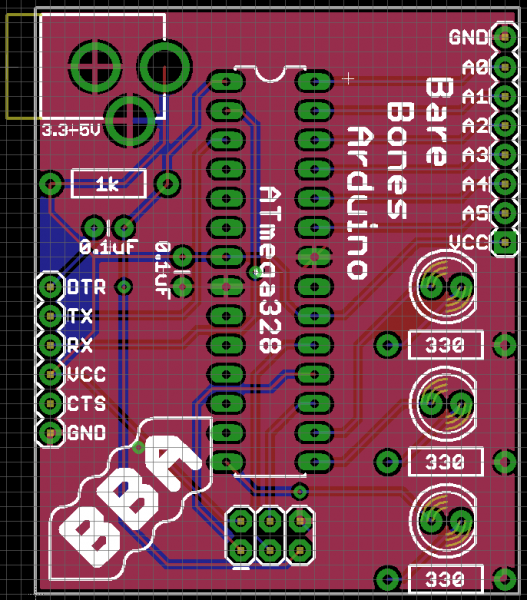

Below is an example of how you might lay out your board while

considering those factors. We’ve minimized airwire intersections by

cleverly placing the LEDs and their current-limiting resistors. Some

parts are placed where they just

have to go (the barrel jack, and decoupling capacitor). And the layout is relatively tight.

Note: The tNames layer (which isn’t visible by default) was turned on to help identify which part is which.

Adjusting the Dimension Layer

Now that the parts are placed, we’re starting to get a better idea of

how the board will look. Now we just need to fix our dimension outline.

You can either move the dimensions lines that are already there, or

just start from scratch. Use the DELETE tool –

– to erase all four of the dimension lines.

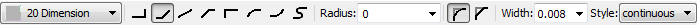

Then use the WIRE tool – (

– to draw a new outline. Before you draw anything though, go up to the options bar and

set the layer to 20 Dimension. Also up there, you may want to turn down the width a bit (we usually set it to 0.008").

Then, starting at the origin, draw a box around your parts. Don’t

intersect the dimension layer with any holes, or they’ll be cut off!

Make sure you end where you started.

That’s a fine start. With the parts laid out, and the dimension adjusted, we’re ready to start routing some copper!

Routing the Board

Routing is the most fun part of this entire process. It’s

like solving a puzzle! Our job will be turning each of those gold

airwires into top or bottom copper traces. At the same time, you also

have to make sure not to overlap two different signals.

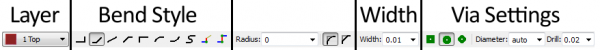

Using the Route Tool

To draw all of our copper traces, we’ll use the ROUTE tool–

– (not the WIRE tool!). After selecting the tool, there are a few options to consider on the toolbar above:

- Layer: On a 2-layer board like this, you’ll have to choose whether you want to start routing on the top (1) or bottom (16) layer.

- Bend Style: Usually you’ll want to use 45° angles for your routes (wire bend styles 1 and 3), but it can be fun to make loopy traces too.

- Width: This defines how wide your copper will be.

Usually 0.01" is a good default size. You shouldn’t go any smaller than

0.007" (or you’ll probably end up paying extra). Wider traces can allow

for more current to safely pass through. If you need to supply 1A

through a trace, it’d need to be much wider (to find out how much,

exactly, use a trace width calculator).

- Via Options: You can also set a few via

characteristics here. The shape, diameter, and drill can be set, but

usually the defaults (round, auto, and 0.02" respectively) are perfect.

With those all set, you start a route by left-clicking on a pin where

a airwire terminates. The airwire, and connected pins will “glow”, and a

red or blue line will start on the pin. You finish the trace by

left-clicking again on top of the other pin the airwire connects to.

Between the pins, you can left-click as much as you need to “glue” a

trace down.

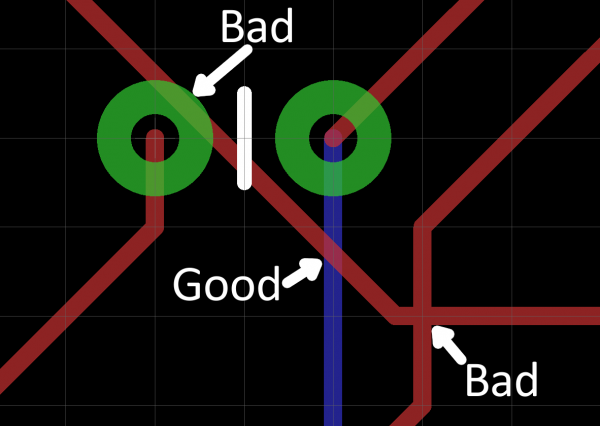

While routing it’s important to avoid two cases of overlap: copper

over vias, and copper over copper. Remember that all of these copper

traces are basically bare wire. If two signals overlap, they’ll short

out, and neither will do what it’s supposed to.

If traces do cross each other, make sure they do so on opposite sides

of the board. It’s perfectly acceptable for a trace on the top side to

intersect with one on the bottom. That’s why there are two layers.

If you need more precise control over your routes, you can hold down

the ALT key on your keyboard to access the alternate grid. By default,

this is set to be a much more fine 0.005".

Placing Vias

Vias are really tiny drill holes that are filled with copper. We use

them mid-route to move a trace from one side of the board to the other.

To place a via mid-route, first left-click in the black ether between

pins to “glue” your trace down. Then you can either change the layer

manually in the options bar up top, or

click your middle mouse button to swap sides. And continue routing to your destination. EAGLE will automatically add a via for you.

Route Clearance

Make sure you leave enough space between two different signal traces.

PCB fabricators should have clearly defied minimum widths that they’ll

allow between traces – probably around 0.006" for standard boards. As a

good rule-of-thumb, if you don’t have enough space between two traces to

fit another (not saying you should), they’re too close together.

Ripping Up Traces

Much like the WIRE tool isn’t actually used to make wires, the DELETE

tool can’t actually be used to delete traces. If you need to go back

and re-work a route, use the

RIPUP tool –

– to remove traces. This tool turns routed traces back into airwires.

You can also use UNDO and REDO to back/forward-track.

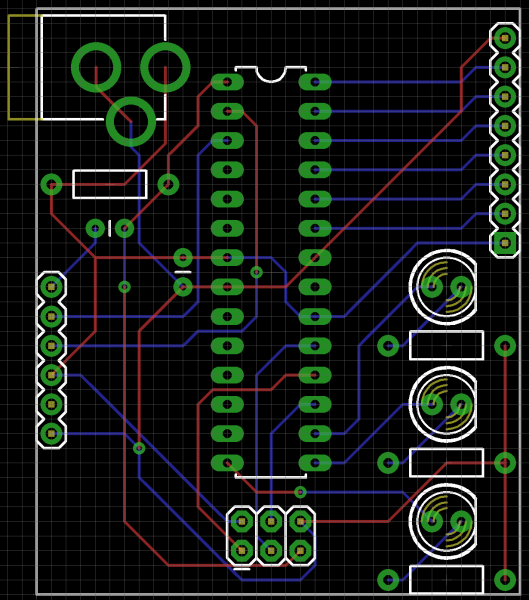

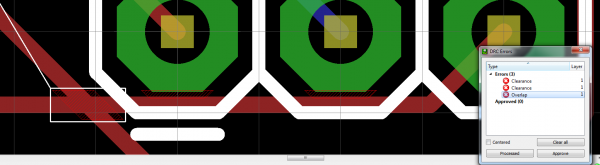

Route Away!

That’s about all the simple rules there are. Go have the time of your

life solving the routing puzzle! You may want to start on the closest,

easiest traces first. Or, you might want to route the important signals –

like power and ground – first. Here’s an example of a fully-routed

board:

See if you can do a better job than that! Make your board smaller. Or try to avoid using any vias.

After you feel like the routing is done, there are a few checks we

can do to make sure it’s 100% complete. We’ll cover those on the next

page.

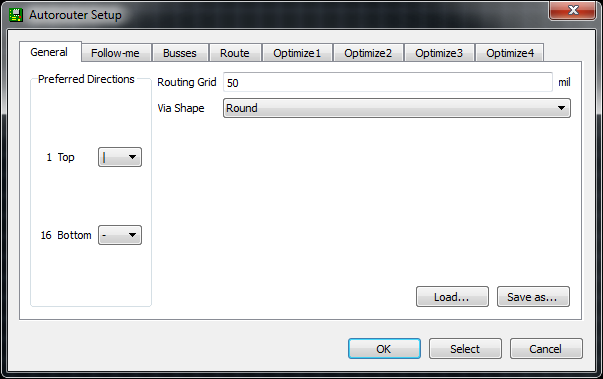

Or Use the Autorouter (Cheater!)

If you’re short on time, or having trouble solving the routing puzzle, you can try loading up EAGLE’s Autorouter –

– to see if it can finish the job. Open up the autorouter, don’t worry about these other tabs for now, just click

OK.

If you don’t like the job the autorouter did, you can quickly hit

Undo to go back to where you were.

The autorouter won’t always be able to finish the job, so it’s still

important to understand how to manually route pads (plus manual routes

look

much better). After running the autorouter, check the

bottom-left status box to see how it did. If it says anything other than

“OptimizeN: 100% finished”, you’ve still got some work to do. If your

autorouter couldn’t finish the job,

try turning Routing Grid down from 50mil 10mil.

There are tons of optimizations and settings to be made in the

autorouter. If you want to dig deeper into the subject, consider

checking out EAGLE’s manual where an entire chapter is devoted to it.

Checking for Errors

Before we package the design up and send it off to the

fabrication house, there are a few tools we can use to check our design

for errors.

Ratsnest – Nothing To Do!

The first check is to make sure you’ve actually routed all of the nets in your schematic. To do this, hit the RATSNEST icon –

– and then immediately check the bottom left status box. If you’ve routed everything, it should say “Ratsnest: Nothing to do!”

As denoted by the exclamation mark, having “nothing to do” is very exciting. It means you’ve made every route required.

If ratsnest says you have “N airwires” left to route, double check

your board for any floating golden lines and route them up. If you’ve

looked all over, and can’t find the suspect airwire, try turning off

every layer except

19 Unrouted.

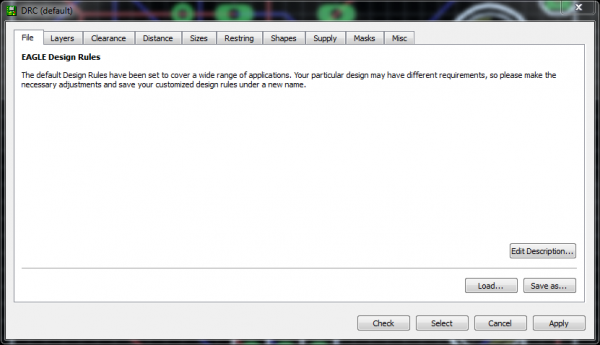

Design Rule Check

Once you’re done routing there’s just one more check to be made: the

design rule check (DRC). For this step, we recommend you use the

SparkFun design rules, which you can download

here. To load up the DRC, click the DRC icon –

– which opens up this dialog:

The tabs in this view (Layers, Clearance, Distance, etc.) help define

a huge set of design rules which your layout needs to pass. These rules

define things like minimum clearance distances, or trace widths, or

drill hole sizes…all sorts of fun stuff. Instead of setting each of

those manually, you can load up a set of design rules using a DRU file.

To do this,

hit Load… and select the

SparkFun.dru

file you just downloaded. The title of the window will change to “DRC

(SparkFun)”, and some values on the other tabs will change. Then

hit the Check button.

Again, look down to the bottom-left of the editor. If your design is

perfect, you should see “DRC: No errors.” But if things didn’t go so

swell, you’ll instead be greeted by the dreaded “DRC Errors” window. The

error window lists all of the open errors, and it also highlights where

the error is. Click on any of the errors listed, and EAGLE will point

to the offender.

There are all sorts of errors that the DRC can find, but here are some of the most common:

- Clearance: A trace is too close to either another trace or a via. You’ll probably have to nudge the trace around using the MOVE tool.

- Overlap: Two different signal traces are

overlapping each other. This will create a short if it’s not fixed. You

might have to RIPUP one trace, and try routing it on the other side of

the board. Or find a new way for it to reach its destination.

- Dimension: A trace, pad, or via is intersecting

with (or too close to) a dimension line. If this isn’t fixed that part

of the board will just be cut off.

Once you’ve seen both “No airwires left!” and “DRC: No errors.”, your

board is ready to send to the fab house, which means it’s time to

generate some gerber files. Before we do that though, let’s add some

finishing touches to the design.

Finishing Touches

Adding Copper Pours

Copper pours are usually a great addition to a board. They look

professional and they actually have a good reason for existing. Not to

mention they make routing

much easier. Usually, when you’re adding a copper pour it’s for the ground signal. So let’s add some ground pours to the design.

Start by selecting the POLYGON tool –

. Then (as usual), you’ll need to adjust some settings in the options bar. Select the top copper (1) layer. Also adjust the

Isolate setting which defines how much clearance the ground pour gives other signals, 0.012" for this is usually good.

Next, draw a set of lines just like you did the dimension box. In

fact, just draw right on top of the dimension lines. Start drawing at

the origin, trace all the way around, and finish back at the same spot. A

dotted red box should appear around the dimension of the board.

After you’ve drawn the polygon, you have to connect it to a net using the NAME tool –

.

This works just like naming nets on a schematic. Use that tool on the

dotted red line you just created, and in the dialog that pops up type

“GND”. (Click

here to see an animated GIF of the entire process.)

The last step is to

hit ratsnest, to watch the glorious red pour fill just about the entire area of your board. You’ll probably hate me for telling you this

now, but adding ground pours to your design at the very beginning (after placing parts, before routing) makes manual routing

much easier.

You can (and probably should) have ground pours on both sides of the board, so follow the same set of steps on the bottom layer.

It can be hard to tell what is and isn’t connected to the ground

pour. If you see a black gap separating a pad and the pour, there is no

connection. If you see some traces forming a “target” over the pad,

there is a connection from the pour to that pad.

If you ever want to

hide the polygon (it’s hard to

see other stuff with it on there), use the RIPUP tool on the polygon

border you just drew. Don’t worry, the polygon is still there, just hit

ratsnest to bring it back.

Adding Silkscreen

Although it has no real effect on the circuit your designing,

silkscreen can be a critical part of the PCB design. You want it to look

good, right? Some silkscreen – like part outlines – is automatically

placed on the board because it’s a piece of the part. We can manually

add other information, like labels, logos, and names. A variety of draw

tools – wire (

), text (

), circle (

), arc (

), rectangle (

), and polygon (

) – can be used to draw on the silkscreen layer (

tPlace for top,

bPlace for bottom).

Have fun and explore with these tools. You could add labels for the

headers, or values for the resistors, or even create a nifty logo.

The draw tools are a bit limited, but that doesn’t mean you can’t make it look good!

Generating Gerbers

When you’ve finalized your design, the last step before

sending it off to the fab house is to generate gerber files. Gerber

files are kind of a “universal language” for PCB designs. EAGLE is far

from the only PCB CAD software out there, and its design files are

nothing like those of Orcad or Altium. Fab houses can’t possibly support

every piece of software out there, so we send them the gerber files

instead.

Gerber files – note the plurality – each describe single layers of

the PCB. One gerber might describe the silkscreen, while another defines

where the top copper is. In all, we’ll generate seven gerber files to

send to the fab house.

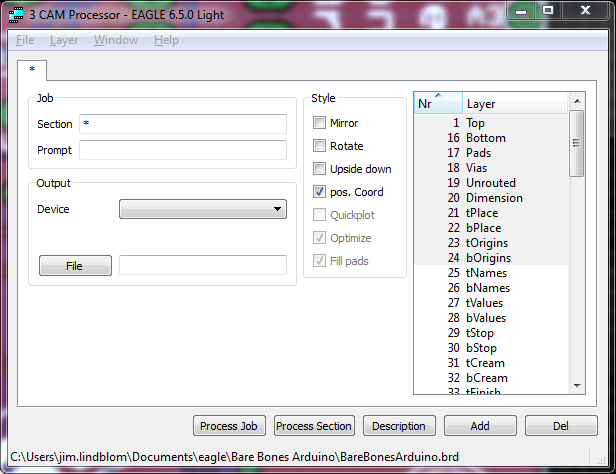

CAM Processor

Before we get too much further, you’ll need to download another definition file:

SparkFun’s CAM file.

Then, load up the CAM processor by clicking the CAM icon –

– which will open up this window:

From here, go to the

File menu, then go

Open > Job…. In the file browser that opens, select the

sfe-gerb274x.cam

file that you just downloaded. Now the CAM processor window should have

a series of tabs: “Top Copper”, “Bottom Copper”, “Top Silkscreen”, etc.

Each of these tabs define how to create one of the gerber files. Now

all you have to do is click

Process Job. If you haven’t saved recently, it’ll prompt you to.

The gerber generation process should be pretty quick. Once it’s run

its course, have a look in your project directory, which should have

loads of new files in it. In addition to the board (BRD) and schematic

(SCH) files, there should now be a .dri, .GBL, .GBO, .GBS, .GML, .gpi,

.GTO, .GTP, .GTS, and a .TXT. Meet the Gerbers!

| Gerber File | Extension |

|---|

| Bottom Copper | GBL |

| Bottom Silkscreen | GBO |

| Bottom Soldermask | GBS |

| Top Copper | GTL |

| Top Silkscreen | GTO |

| Top Soldermask | GTS |

| Drill File | TXT |

| Drill Station Info File | dri |

| Photoplotter Info File | gpi |

| Mill Layer | GML |

| Top Paste | GTP |

(on the top toolbar, or under the File

menu) – which should prompt a new, board editor window to open. All of

the parts you added from the schematic should be there, stacked on top

of eachother, ready to be placed and routed.

(on the top toolbar, or under the File

menu) – which should prompt a new, board editor window to open. All of

the parts you added from the schematic should be there, stacked on top

of eachother, ready to be placed and routed.

– and then click a layer’s number to select or de-select it. Before you

start routing, make sure the layers above (aside from tStop and bStop)

are visible.

– and then click a layer’s number to select or de-select it. Before you

start routing, make sure the layers above (aside from tStop and bStop)

are visible.

. A 0.05" grid, and 0.005" alternate grid is a good size for this kind of board.

. A 0.05" grid, and 0.005" alternate grid is a good size for this kind of board.

– you can start to move parts within the dimension box. While you’re moving parts, you can rotate them by either right-clicking or changing the angle in the drop-down box near the top.

– you can start to move parts within the dimension box. While you’re moving parts, you can rotate them by either right-clicking or changing the angle in the drop-down box near the top. – to get the airwires to recalculate.

– to get the airwires to recalculate.

– to erase all four of the dimension lines.

– to erase all four of the dimension lines. – to draw a new outline. Before you draw anything though, go up to the options bar and set the layer to 20 Dimension. Also up there, you may want to turn down the width a bit (we usually set it to 0.008").

– to draw a new outline. Before you draw anything though, go up to the options bar and set the layer to 20 Dimension. Also up there, you may want to turn down the width a bit (we usually set it to 0.008").

– (not the WIRE tool!). After selecting the tool, there are a few options to consider on the toolbar above:

– (not the WIRE tool!). After selecting the tool, there are a few options to consider on the toolbar above:

– to remove traces. This tool turns routed traces back into airwires.

– to remove traces. This tool turns routed traces back into airwires.

– to see if it can finish the job. Open up the autorouter, don’t worry about these other tabs for now, just click OK.

– to see if it can finish the job. Open up the autorouter, don’t worry about these other tabs for now, just click OK.

– which opens up this dialog:

– which opens up this dialog:

. Then (as usual), you’ll need to adjust some settings in the options bar. Select the top copper (1) layer. Also adjust the Isolate setting which defines how much clearance the ground pour gives other signals, 0.012" for this is usually good.

. Then (as usual), you’ll need to adjust some settings in the options bar. Select the top copper (1) layer. Also adjust the Isolate setting which defines how much clearance the ground pour gives other signals, 0.012" for this is usually good.

.

This works just like naming nets on a schematic. Use that tool on the

dotted red line you just created, and in the dialog that pops up type

“GND”. (Click

.

This works just like naming nets on a schematic. Use that tool on the

dotted red line you just created, and in the dialog that pops up type

“GND”. (Click

), circle (

), circle ( ), arc (

), arc ( ), rectangle (

), rectangle ( ), and polygon (

), and polygon (

– which will open up this window:

– which will open up this window: